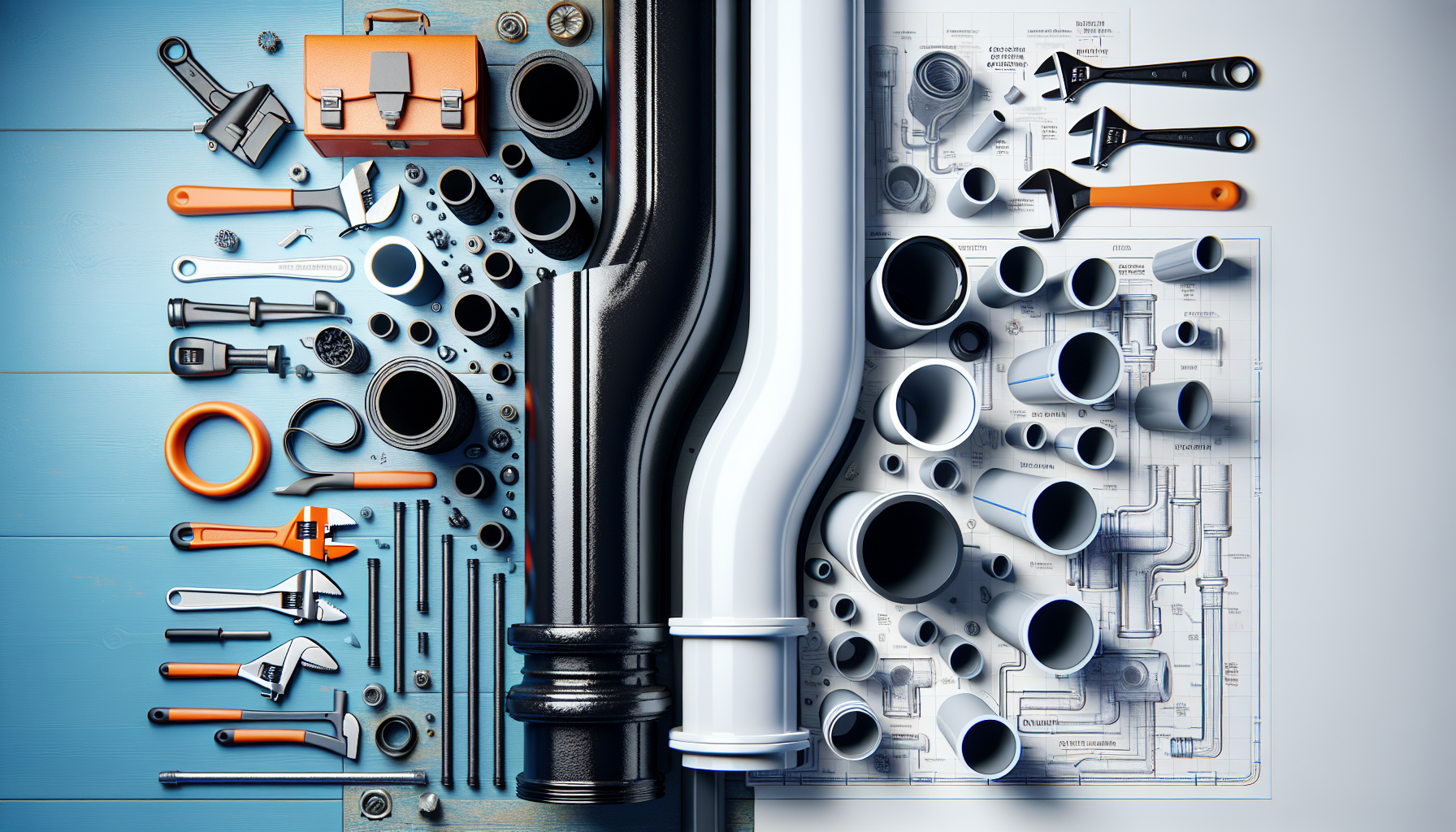

Choosing the right material for drain lines is crucial for the durability, efficiency, and cost-effectiveness of plumbing systems. The debate between using PVC pipes and cast iron has been ongoing, with each material offering distinct advantages and challenges. At the core of this discussion is the pvc pipe cost, which often influences the final decision. Understanding these costs in the context of other factors such as installation ease, durability, and maintenance requirements is vital for homeowners, contractors, and builders alike.

This article will delve into a comprehensive comparison between cast iron and PVC pipes, highlighting the cost implications, including pvc pipe cost alongside other critical aspects such as installation requirements, use of hangers, pipe clamps, thermal expansion, pipe insulation, and fittings. Additionally, it will explore the durability and use cases for both materials, providing recommendations based on various plumbing needs. Through a detailed analysis, readers will gain insights into which piping material is better suited for their specific drain line projects, taking into account both upfront costs and long-term benefits.

Overview of Cast Iron Pipes

Cast iron pipes have been a staple in plumbing systems due to their durability and strength. Historically, they have been used for centuries, with some of the earliest large-scale systems installed in the 17th century, such as the one at Versailles, France. This longevity is a testament to the material’s robustness, making it a preferred choice for critical infrastructure.

Strengths and Weaknesses

Cast iron is renowned for its strength, which allows it to withstand high pressures and harsh treatment that would damage or destroy other types of pipes. This makes it an excellent material for main sewer lines and large drain outlets. However, cast iron is not without its drawbacks. It is susceptible to corrosion over time, especially when exposed to moist or acidic environments. This corrosion can lead to leaks and structural weakness, necessitating regular inspections and maintenance.

Historical Use and Durability

The use of cast iron pipes dates back to the 17th century, showcasing a track record of durability and effectiveness. Notably, the cast iron piping system installed at Versailles in 1664 is still functional today, more than three centuries later. Cast iron’s longevity is further evidenced by its widespread use in the 19th century across American cities, where it was the material of choice for municipal water and sewage systems.

Fire Resistance and Safety

One of the significant advantages of cast iron is its fire resistance. Unlike plastic pipes, cast iron does not melt or burn, making it a safer choice in environments where fire risk is a concern. Its ability to withstand high temperatures without losing integrity adds an extra layer of safety in commercial and residential buildings.

Noise Dampening Qualities

Cast iron pipes offer superior noise reduction compared to other piping materials. The dense metal significantly reduces the sound of flowing water and other noises typically associated with plumbing systems. This quality makes cast iron an ideal choice for buildings where noise reduction is crucial, such as hotels, hospitals, and high-rise residential buildings.

Maintenance and Longevity

While cast iron pipes are durable, they require maintenance to prevent issues such as corrosion and clogging. Regular inspections can identify potential problems early, extending the lifespan of the piping system. With proper care, cast iron pipes can last for decades, often outliving the buildings they are installed in. Additionally, their ability to be recycled after their useful life further enhances their appeal as a sustainable plumbing solution.

In conclusion, cast iron pipes offer a combination of durability, safety, and functionality that makes them a compelling choice for various plumbing applications. Despite their susceptibility to corrosion, their advantages often outweigh the disadvantages, particularly in settings where longevity and safety are priorities.

Overview of PVC Pipes

PVC pipes, known for their versatility and cost-effectiveness, are widely used in various plumbing and drainage systems. This section explores the strengths and weaknesses, ease of installation, cost efficiency, environmental impact, and durability and flexibility of PVC pipes, providing a comprehensive overview that highlights why they are a preferred choice in many scenarios.

Strengths and Weaknesses

PVC pipes are celebrated for their light weight, resistance to corrosion, and high strength-to-weight ratio. They are chemically inert, meaning they do not react with the contents they carry, which is particularly advantageous for carrying aggressive substances without degrading. Additionally, PVC’s ability to be solvent-welded creates strong, leak-proof joints. However, PVC is not without its limitations. It has a lower temperature threshold and can become brittle when exposed to UV rays or extremely cold environments. Its production involves toxic chemicals like vinyl chloride, which pose health risks during manufacturing.

Ease of Installation

One of the most significant advantages of PVC pipes is their ease of installation. These pipes are lightweight, making them easy to transport and handle on-site. They can be cut and connected more straightforwardly than metal pipes, reducing labor costs and installation time. This ease of installation makes PVC a popular choice among contractors and DIY enthusiasts alike.

Cost Efficiency

PVC pipes are generally less expensive than their metal counterparts, primarily due to the lower cost of the raw materials and the ease of manufacturing. The installation costs are also lower because PVC can be installed more quickly and does not require specialized tools or skills. Over time, the durability of PVC minimizes the need for replacements and repairs, contributing to its overall cost-effectiveness.

Environmental Impact

While PVC pipes have a lower carbon footprint in production compared to other materials like concrete and metals, their environmental impact is a mixed bag. PVC is recyclable, and its lightweight nature reduces transportation emissions. However, the recycling process is complex and not always feasible, leading to potential environmental hazards if not disposed of properly. The production of PVC also releases dioxins and other harmful chemicals, raising concerns about its long-term sustainability.

Durability and Flexibility

PVC pipes are known for their long lifespan; they can last up to 100 years under optimal conditions. This durability is due to their high resistance to environmental factors that typically degrade other materials, such as moisture, insects, and chemicals. While PVC is not as flexible as some other plastics, it can accommodate moderate bends and curves with the appropriate techniques, such as heating, which makes it versatile for various applications. However, care must be taken in extremely cold climates, as PVC can become brittle and prone to cracking.

In summary, PVC pipes offer a robust set of advantages that make them suitable for a wide range of applications. Their inherent weaknesses are counterbalanced by their benefits in cost, ease of installation, and longevity, making them a compelling choice for both new construction and renovation projects.

Detailed Comparison: Cast Iron vs. PVC

Cost Analysis

When comparing the costs of cast iron and PVC pipes, several factors come into play. Cast iron pipes are generally more expensive both in terms of initial material costs and installation. This is due to the material’s robustness and the labor-intensive process required for its installation. Cast iron is heavier and denser, making it more challenging to transport and handle, which can lead to increased labor costs. On the other hand, PVC pipes are much more cost-effective. The lightweight nature of PVC significantly reduces labor expenses, and the manufacturing process is less costly, reflecting in the consumer price.

Ease of Installation and Maintenance

PVC pipes offer a distinct advantage in terms of installation and maintenance. Their lightweight nature makes them easier to transport, handle, and install, which can lead to quicker installation times and lower labor costs. Cast iron, being significantly heavier, requires more labor-intensive handling and installation processes. In terms of maintenance, cast iron may require more frequent inspections for rust or leaks and potential repairs due to its susceptibility to corrosion over time. PVC, being resistant to corrosion, generally demands less maintenance, adding to its appeal in terms of ease of upkeep.

Safety Concerns

Safety is a critical consideration in material selection for plumbing. Cast iron pipes offer superior fire resistance as they do not burn or melt, making them a safer choice in environments where fire risk is a concern. In contrast, PVC pipes can emit dangerous fumes when exposed to fire, posing health hazards. Furthermore, the need for complex firestopping systems with PVC in fire wall penetrations adds to the safety concerns and installation costs.

Sound Dampening

Noise reduction is another important factor in the selection of piping materials. Cast iron pipes are known for their excellent sound dampening properties due to their dense molecular structure. This makes them ideal for use in settings such as hotels, hospitals, and residential buildings where minimizing noise is crucial. PVC pipes, however, tend to transmit sound more effectively, which could be a drawback in environments where noise levels are a concern.

Environmental Impact

The environmental impacts of both materials are significant yet varied. Cast iron pipes, while made from about 10% post-consumer scrap iron, contribute to CO2 emissions, air pollution, and solid waste during manufacturing. However, they can be recycled, reducing the need for raw material extraction. PVC pipes, although less impactful in terms of CO2 emissions during production, involve the use of petroleum-derived materials and release dioxins and other harmful chemicals during manufacturing. Their disposal poses challenges as they are not biodegradable, potentially leading to long-term environmental hazards.

Use Cases and Recommendations

Residential Applications

Cast iron pipes have been historically revered for their durability and longevity, making them a staple in older homes, particularly those built before the 1970s. These pipes are known for their robustness, often lasting decades, if not a century, with proper maintenance. However, they are susceptible to corrosion and rust, which can lead to significant maintenance issues over time. In residential settings, especially in areas with older housing infrastructure, cast iron pipes may still be in use but might require regular inspections and maintenance to prevent serious plumbing issues.

On the other hand, PVC pipes are favored in modern residential constructions due to their lightweight, corrosion resistance, and ease of installation. They are particularly advantageous in new constructions and renovations where quick and cost-effective plumbing solutions are preferred. PVC pipes are also beneficial in areas prone to acidic soil conditions where metal pipes would deteriorate quickly.

Commercial Applications

In commercial environments, the choice between PVC and cast iron pipes can depend heavily on the building requirements and local codes. Cast iron pipes are often mandated in multi-unit structures and commercial properties for their superior noise reduction capabilities and fire resistance. These properties make cast iron an ideal choice for buildings where plumbing noise could be a disturbance, such as in hotels, hospitals, and apartment complexes.

PVC pipes, while not suitable for all commercial applications due to their flammability and noise transmission, are often used in low-rise commercial constructions or in non-critical areas due to their lower cost and ease of installation. They are also commonly used in sprinkler systems and secondary water lines where high durability against heat is not a primary concern.

Regulations and Code Requirements

Building codes and local regulations play a crucial role in determining whether PVC or cast iron should be used. Some jurisdictions specifically require the use of cast iron in certain types of constructions due to its fire-resistant properties and ability to reduce noise. For instance, cast iron is preferred in high-rise buildings or healthcare facilities where safety and quiet are paramount.

Conversely, PVC may be favored in residential constructions or areas where the chemical stability and cost-effectiveness of PVC provide significant advantages. It’s important for builders and developers to consult local building codes and standards, which can vary significantly from one region to another, to ensure compliance with all regulatory requirements.

Expert Opinions

Experts in plumbing and construction often emphasize the importance of choosing the right material based on specific use cases and environmental conditions. They recommend cast iron for applications where durability, noise reduction, and fire resistance are critical. Meanwhile, PVC is suggested for scenarios where cost, chemical resistance, and ease of installation are more significant concerns.

Professionals also advise regular inspections and maintenance regardless of the materials used, especially for older systems that might be prone to degradation or those installed in harsh environmental conditions. Trenchless technology and pipe relining are also recommended for repairing older pipe systems without the need for extensive excavation and disruption.

In summary, both PVC and cast iron pipes have their specific applications and benefits. Decision-makers should consider factors such as environmental conditions, building requirements, cost implications, and long-term maintenance needs when selecting the appropriate plumbing materials.

Conclusion

Through a comprehensive exploration of the advantages and disadvantages associated with both PVC and cast iron pipes, it is evident that the choice of material hinges on the specific requirements of the plumbing project, be it residential or commercial. PVC stands out for its cost-efficiency, ease of installation, and resistance to corrosion, making it an attractive option for budget-conscious projects and modern constructions. Conversely, cast iron pipes, with their unparalleled durability, fire resistance, and sound dampening qualities, are particularly suited for applications where safety, longevity, and noise reduction are primary concerns.

Ultimately, the decision between PVC and cast iron should be guided by a thorough consideration of the project’s unique demands, environmental factors, and local building codes and regulations. Whether prioritizing the long-term benefits of cast iron’s robustness and safety features or leveraging the cost savings and versatility of PVC, it is crucial for decision-makers to weigh these factors diligently. By doing so, they can ensure the selection of the most appropriate, efficient, and sustainable piping material, tailored to the specific needs of their construction or renovation projects.

FAQs

- Which material is more suitable for sewer lines, PVC or cast iron? Cast iron is a robust material but can become brittle and break under blunt force. In contrast, PVC is flexible, highly resistant to blunt impacts, and less likely to break, making it a more suitable choice for sewer lines.

- What type of pipe is recommended for drainage systems? PVC pipes are highly recommended for drainage systems. They offer excellent strength, durability, and resistance to corrosion. Additionally, they are cost-effective, easy to install, and can withstand the weight of soil and water without being damaged by roots or debris.

- What is the preferred material for drain lines in residential settings? PVC is the preferred choice for residential drain lines, having been the leading option for the past four decades. It is a durable, light-colored plastic that withstands various environmental factors. PVC is available in different grades, such as Schedule 40, Schedule 80, and chlorinated polyvinyl chloride (CPVC), each suited to different uses.

- Is PVC pipe more affordable than cast iron pipe? PVC pipe is notably less expensive than cast iron. For instance, a 10-foot section of 4-inch Schedule 40 PVC pipe costs about $18, whereas the same length of 4-inch hub-less cast iron pipe costs approximately $58. This price difference represents a significant saving of about 70 percent, making PVC a cost-effective alternative. Additionally, PVC is easier to install, adding to its overall cost benefits.

Everyone’s responsibility at American Claims Ensurance is to take care of you, the homeowner or business owner. Dealing with the insurance company can be a time consuming, complicated and stressful process, and that is when an experienced and trusted American Ensurance public adjuster is needed.

Give American Claims Ensurance a call at 800-204-2463 or go to acepublicadjusters.com to find out how we can help you.